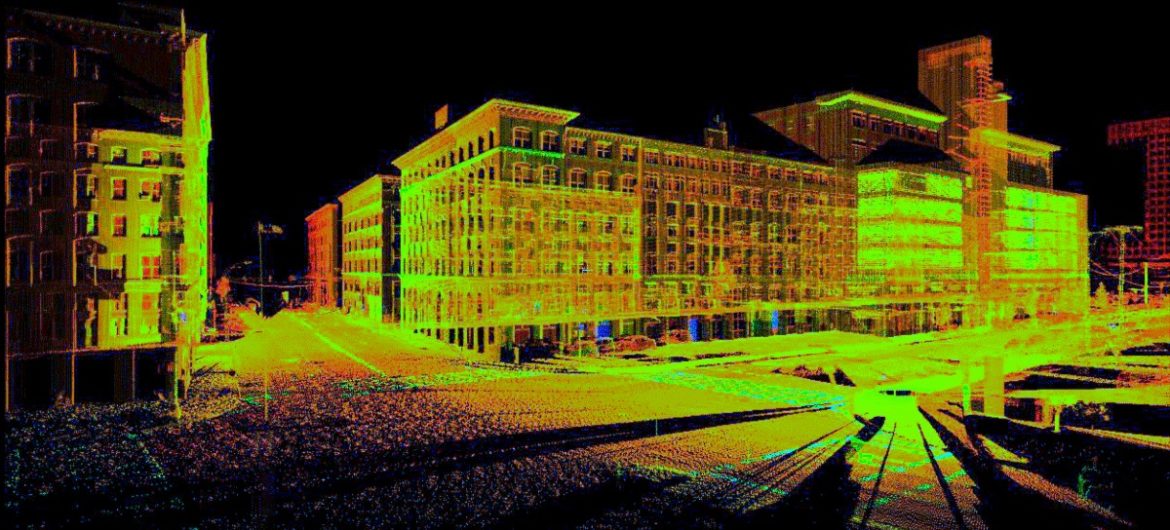

3D scanning is something that you would think came straight out of a science-fiction movie. Completely unimaginable in the real world just a few decades ago, it is one of the latest innovations with the potential to change the world.

3D scanning uses laser light to capture the shape of a physical object digitally. By using the laser to create “point clouds” of data, 3D scanners are able to capture the exact size and shape of an object and render it onto a computer.

This allows 3D scanning to be useful in a number of industries where manufacturing is required, such as the construction and medical industries. At the same time, 3D laser scanning has also provided invaluable services to historians and archaeologists in helping study, reconstruct, and restore historical artifacts. Thus, the demand for 3D scanning in Utah and the rest of the United States has significantly increased in recent years.

Here are some of the ways in which 3D scanning can prove incredibly useful:

Save time when designing an object

If a new object or part is to be manufactured, the typical process involves creating a prototype first. This, in itself, can take a very long time, as a new one has to be created each time modification in the design is made.

3D scanning can greatly speed up this process, as it allows the manufacturer and designer to clearly identify where an object is warped as well as what the necessary adjustments are. This can reduce the number of prototype cycles necessary, thus saving much time and effort during the design process.

Make remanufacturing parts much easier

Although it was possible to remanufacture a replacement for a missing or old part before the creation of 3D scanning, this process could be quite time-consuming and expensive. This is because manufacturers had to ensure that the specifications of the replacement part were exactly correct so that the parts would fit and work perfectly together.

3D scanning, however, has been able to simplify this process and make it much easier greatly. Because of its ability to deliver highly precise specifications and data, it is now possible to create a representation that is accurate enough to be used in the manufacturing process at the first try, thus saving much time and resources.

Increased quality control

The precision of 3D scanning allows for the checking of every aspect of the object, from the quality of design to its composition and stability, down to the most precise measurements. This greatly improves the ability to check if the object was well-designed to match the intended specifications or not and to observe what modifications need to be made if there are any. This also ensures that the products to be manufactured will definitely be of good quality.

Compare designs with the actual products

One of the major benefits of 3D scanning is that it allows for a very accurate comparison between the original design and the actual manufactured product. This allows manufacturers to check how precisely they followed the original design, which is an important metric of success in the manufacturing industry.

More than being a simple metric, however, it also helps the manufacturer produce quality products that will serve their intended purpose. This helps improve the way the manufacturer does business, thus enhancing its reputation and increasing the likelihood of earning more business opportunities in the future.