Fiberglass reinforced plastic, or FRP for sale online, is a unique material that combines the strength and durability of fiberglass with the versatility and low maintenance requirements of plastics. It is widely used in many industries for a variety of applications due to its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. Let’s take a closer look at what makes FRP such a powerful material.

What is Fiberglass Reinforced Plastic?

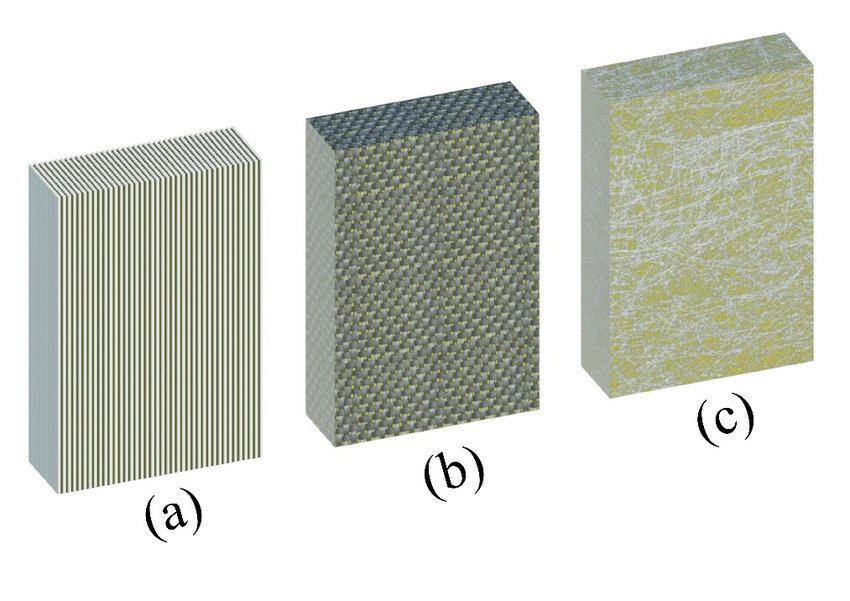

Fiberglass reinforced plastic (FRP) is a composite material made up of two distinct components – fiberglass and plastic resin. The layer of fiberglass provides structural strength while the layer of plastic resin acts as an adhesive to hold it all together. Additionally, FRP can also be combined with other materials like carbon fiber or Kevlar in order to enhance its properties even further.

The Benefits of FRP

One of the main benefits of fiberglass reinforced plastic is its high strength-to-weight ratio. This makes it ideal for applications where weight reduction is critical, such as aerospace components or boat hulls. Additionally, FRP is highly resistant to corrosion, making it perfect for use in wet environments like marine vessels or sewage plants. It also has excellent thermal insulation properties which makes it well suited for use in refrigeration units or hot water tanks. Finally, FRP can be easily molded into complex shapes which allows designers more freedom when creating new products and structures.

FRP Applications

Given its impressive combination of properties, there are many different applications for FRP materials – from industrial piping systems to aircraft fuselages! In automotive applications, FRPs are often used for body panels due to their lightweight nature and corrosion resistance; in construction projects they are used as reinforcing bars in concrete forms; and in medical equipment they are used as protective coatings on implants and prosthetics due to their biocompatibility. Additionally, since they can be easily colored or textured they can even be used as decorative elements both indoors and outdoors!

Fiberglass reinforced plastic (FRP) has proven itself time and again as one of the most versatile materials available today thanks to its impressive combination of strength and durability along with its resistance to corrosion, temperature extremes, and easy moldability into complex shapes. Whether you need a lightweight solution for your next aerospace project or are looking for something more decorative for your home renovation project – look no further than FRP!

Fiberglass reinforced plastic (FRP) is an incredibly versatile material with numerous applications across various industries. Its lightweight yet strong properties make it an ideal choice for applications that require strength and durability without adding unnecessary weight or cost. Its corrosion resistance also makes it an attractive option for areas with high exposure to water or chemicals while its thermal insulation properties make it suitable for use in areas where temperature fluctuations are common.

FRP products can be found in a variety of forms including sheets, tubes, rods, molded parts and more. Its use as an alternative to traditional materials such as wood and metal is on the rise due to its versatility and cost-effectiveness. From aerospace components to chemical tanks, FRP can meet the needs of virtually any application.