As the idea of environmental conservation rises, reducing power draw has been a great concern for the emission created during the process. While the rise of ocean level 100 years later might not be a great reason for you to turn off the lights when leaving a room, reducing the monetary figure on your power bills might be.

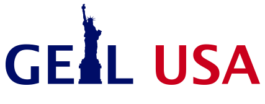

To understand how a variable frequency drive (VFD) can help you, a basic understanding of it is needed. Most VFDs on sale and in use nowadays are using a pulse width modulation technology. In laymen terms, a series of voltage and current change encourage curved electricity waves in different electricity frequency to modulate the speed of motors.

VFDs can be used from small devices to large compressors to encourage efficient use of electricity. An approximate of 25% of electrical energy in the world is used by electrical motors. The amount of energy saved if VFDs are implemented to all motors are incredible, might also be an impressive save in your electricity bill.

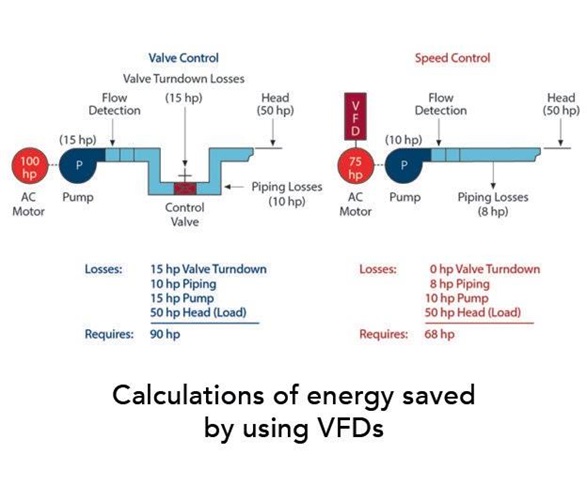

So how does VFD help with energy saving and the money you pay to burn extra historic remains? The benefit of using VFDs is most noticeable in variable torque load conditions, despite enhancing efficiency for all motors (to be discussed). Because of the “affinity laws” which stated “if the speed of a fan is cut in half, the horsepower needed to run the fan is cut by 1/8”, a motor that runs according to the load will reduce energy consumption over a motor running in constant speed regardless of the load.

A calculation on the benefits of VFDs has shown a 45% reduction of energy use with VFD influence to a 25-horsepower motor running 23 hours per day. At the Victorian electricity rate of around $27.56c/kWh, using VFDs can save approximately 14,900 Australian dollars annually.

The ability to control the motor is also a huge plus from using VFDs. As called ramped acceleration and ramped stopping, VFDs allow progressive building and slowing speed of the motor, which not only reduces energy consumption, but also extends the motor life with less mechanical wear.

As a bonus from ramped acceleration, the missing of the huge initial power drain of the motor keeps the voltage supplied to other equipment relatively constant to prevent sensitive instruments, like the computers, to trip offline. The limited power drain also helps with avoiding shocks to machines with a sudden power outage and input.

Additional benefits with VFDs include reverse operation. Gone are the needs for a reversing starter as electronic ability reversing can be integrated or added to a VFD for eliminating the cost of a reversing started and reducing space required. Not for everyone, but VFDs could potentially eliminate the need for gearboxes as well with its variability to voltage and current.

The benefits of VFDs in cost-saving extend beyond reduced electricity cost to elimination of unnecessary equipment, lowered maintenance cost and the long-term cost for replacing the motor eventually with the increased longevity of the motors. If you want to know more about VFD, visit the principle of operation of VFD.