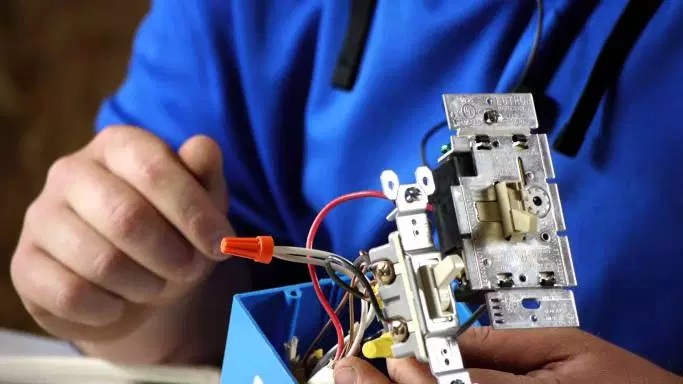

There are various sorts of electrical and electronic wire and link accessible. They run from single conductor to multi-conductor link. The measure of conductors that fit in one link is practically boundless seeing as there are 300 sets links accessible. The single transmitter wires are typically made with uncovered copper, yet can likewise be made with aluminum. The aluminum wires are to a lesser extent a transmitter so you would require a greater size to complete something very similar.

The single conveyor wires are otherwise called connect wire. Some have PVC protection and are evaluated for just indoor use and some electrical wire has a nylon covering over it for climate assurance against downpour, gas and solvents. There is likewise a teflon wire utilized for high temperature applications in the 200 degrees Celsius run. All single conduit wires have distinctive stranding choices accessible in light of the fact that the stranding decides the adaptability. A strong strand of copper will be stiffer which is exceptionally suggested for electrical use when going through course. That way it will push through simpler and wont pack up en route. The higher strand checks have much better adaptability where the wire should be folded over a couple of corners or around. Most stranded attach wires can pretty much fold over your finger.

Above all else, I need to clarify the distinction between multi-conductor and multi-combined links. A 5 transmitter link is comprised of 5 wires with and over all coat. A 5 sets link is comprised of 5 wound sets, which is really 10 wires separated into sets and bent together. The fundamental use for that is the point at which an electrical temporary worker is wiring a home with a 10 sets link he/she begins with the 10 sets at the electrical box and starts severing from that point. They will run the link to the upstairs and carry 2 sets to one room, 2 sets to another room, etc. The stranding for electronic links are for the most part however many as could be allowed without being intemperate. They need it to be adaptable to circumvent corners and clear its path through the dividers.

Wire is made to be a transmitter of power, but at the same time there’s a great deal to consider when talking about the protection too. Some are climate safe, high temperature or high voltage. PVC is the shabby stuff that is made for indoor utilize as it were. They can likewise add to PVC and make it downpour, gas and dissolvable safe which would be useful for open air use at the edge of a structure or in channel. At that point they make an elastic coat which has the rough form to it for product and tare reasons. Once in a while you’ll require a long link to keep running over a place of work that can be stepped on, hauled, scratched against a structure and even keep running over by machines. The elastic coat is additionally totally climate safe.

Once in a while protection is flawlessly adaptable in the mid year however extremely solid when the chilly climate comes. They’ve made a protection that stick focuses that issue and keeps the full adaptability regardless of whether you left the link in the snow for seven days (when you get the ice off of it obviously). You’ll see this more in the additional string items since they’re run outside regularly and need to look after adaptability.

As should be obvious, there are a wide range of varieties of wire and link accessible. So you should converse with a specialist to ensure you’re getting precisely what you requirement for the application that you have. Tell them what you’re utilizing it for and they ought to have the option to give you a few pointers about what the best choices are. At that point you can settle on your decision dependent on cost and conveyance time.